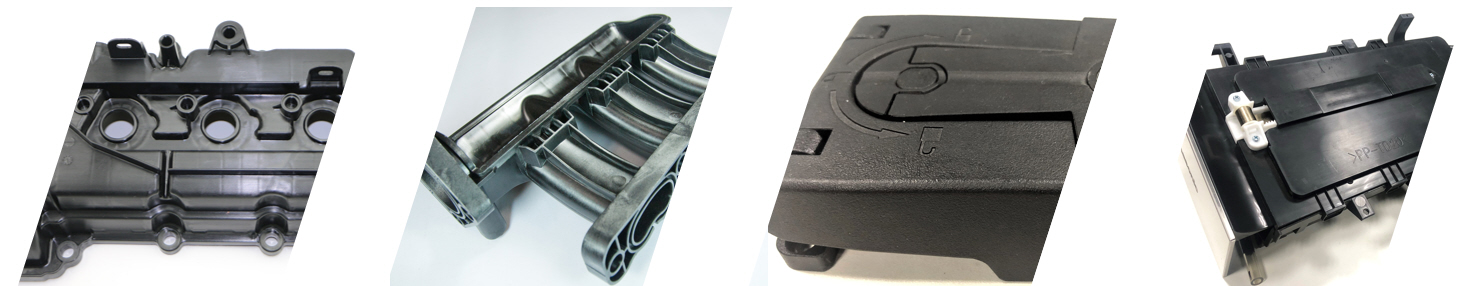

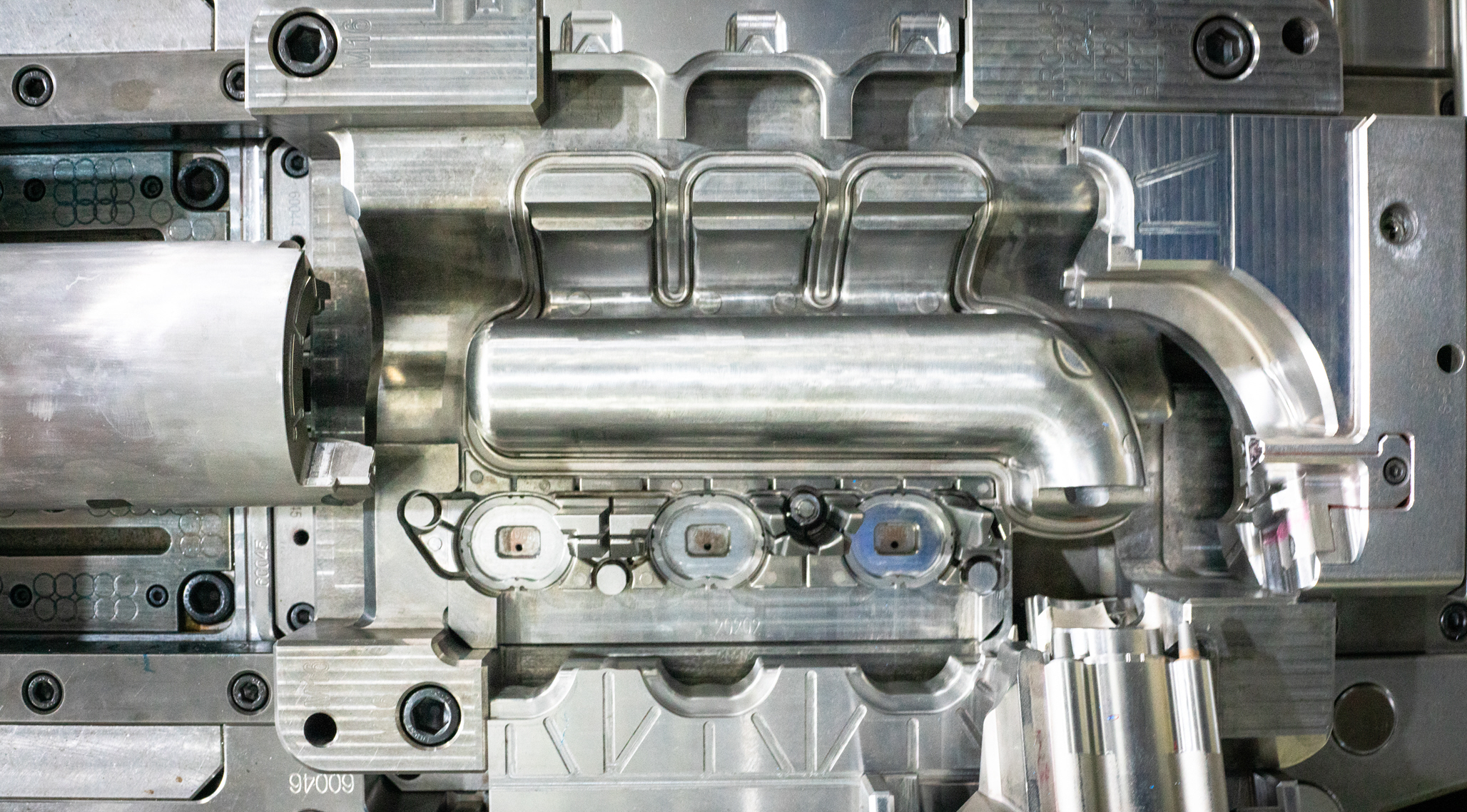

AUTOMOTIVE ENGINE COMPONENTAUTOMOTIVE ENGINE COMPONENT

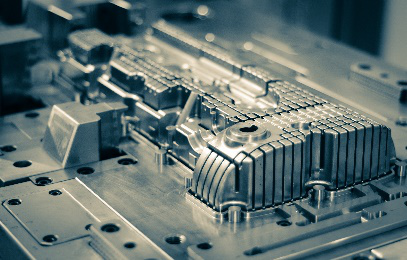

OVER-MOLDING Due to part design issue, we have to consider over-molding otherwise it’s not feasible for tooling. The 1st component will be carried into 2nd station by robot hand, and then finish the part. Both of the material is PA6+GF with excellent finish. Over-molding with thread inserts or other metal parts is also popular in our tools. |